You’ve always been fond of printing your own shirts at home, but since a few people have taken an interest in your designs, you figured you’d turn your hobby into your own shirt printing business.

But considering you’re just starting, you currently don’t have a lot of funds to invest in equipment like a heat press.

Since the closest thing you have at home is a flat iron, you wonder if it would be enough to fulfill your orders.

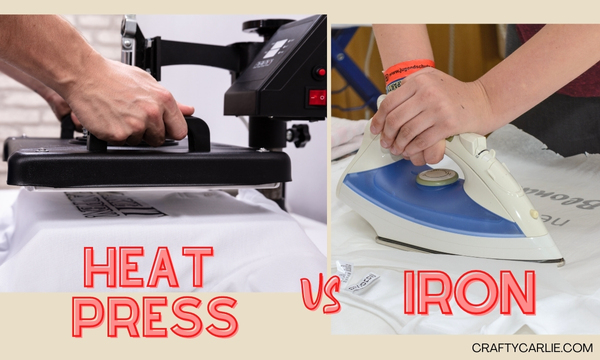

So to help you weigh in on the pros and cons, this article will break down the differences between a heat press and a flat iron. So if you’re ready to know more, follow along below.

What’s the difference between a heat press and an iron?

When working with heat transfer designs, you’ll need sufficient heat and pressure to neatly press your design onto a shirt.

That’s why you probably used your clothes iron when first learning to create your craft.

But does an iron work the same as a heat press?

At its core, an iron can give off the required heat to press a heat transfer print onto a shirt. But since it’s not designed for shirt printing, it doesn’t have the same features that a heat press machine has.

A good quality heat press would include a timer, temperature, and pressure settings, so it’s even throughout the pressing process. But because it’s an industrial grade, heat presses can be quite pricey when you’re still starting out your business.

Is a heat press better than an iron?

If you print shirts as a hobby, using your flat iron would make sense since you probably already have one at home, and it does the job of pressing your heat transfer designs effectively.

But if you have your own business, a heat press would give higher quality prints since it has more features than your regular clothes iron.

Most heat presses would have a digital timer so you can set how long a vinyl would need to transfer onto your shirt.

Your regular clothes iron can get to 400°F (204°C), enough to transfer your design onto a shirt, but you won’t see the exact temperature you’re working with.

In contrast, a heat press could get up to 450-500°F (232-260°C), and you get to set the exact temperature you’ll need so you won’t have to worry about burning your shirt.

Lastly, since a heat press has built-in plates, your vinyl will have uniform pressure ensuring an even application.

So, in a nutshell, a heat press is better for producing shirt prints.

Can you use a clothes iron instead of a heat press?

When setting up a custom t-shirt business, you want to make sure you have the right materials and equipment you’ll need to produce the best products.

Since you’re going to do a lot of printing, is a heat press necessary, or can you use your iron?

If you’re thinking about starting your own business, you don’t need to wait to save up enough funds to buy your own heat press before you start accepting orders.

Many shirt printing businesses have started by using a clothes iron to press their designs; it just takes more time and elbow grease to finish each shirt.

But as long as you press your designs correctly, a clothes iron can give similar results to how a heat press would.

But once your business starts growing and more orders are coming in, a heat press would come in handy for creating more custom shirts quicker without sacrificing quality.

Do you need a Cricut heat press, or can you use an iron?

Cricut is one of the go-to brands for DIY crafters as they have a variety of crafting essentials, including their heat presses.

Their very first heat press, the Cricut Easypress, came out in 2017 to make heat pressing projects easier and faster. Since then, they came out with 4 more varieties of heat presses so you can have more options to fit your crafting needs.

A Cricut heat press is definitely an upgrade from your regular iron as it includes its own digital timer and temperature settings. Hence, they stay consistent when you’re pressing multiple shirts. You can even connect the machine with your mobile device, so you can control it even when you’re across the room.

It also cuts down the printing time compared to when you’re using a clothes iron as a Cricut heat press heats up faster.

It also has a built-in plate, so you can press larger designs in one go. The only downside is that you still need to apply pressure if you want your design to transfer well unless you get their Cricut Autopress.

Considering its features, a Cricut heat press is pricier than your at-home iron, so you’re not required to get one for your shirt printing business.

But if you’re looking to lighten up your workload and still don’t have the budget to get an industrial-grade heat press, a Cricut heat press is an excellent alternative.

Can I use an iron for heat transfer paper?

A heat transfer paper contains multiple layers that allow a design to melt onto fabric when you apply heat.

A heat press is ideal for giving the best results, but for a startup business, a clothes iron will work well as long as it has 1400 watts or more.

You just need to make sure you’ll apply enough time, heat, and pressure to make your design last on your shirts.

A quick tip is to heat up your iron for about 2 minutes at the highest temperature to ensure it’s hot enough before pressing your design.

When ironing, remember to apply the same pressure when you’re going through every corner to make sure your design sticks evenly.

Lastly, avoid ironing directly on your printed design so the ink won’t transfer onto the iron and ruin your work.

Can I use an iron instead of a heat press for sublimation?

If you’re planning to include sublimation printing in your custom shirt business, using an iron for this method is not recommended as it won’t give you the best results.

Sublimation ink needs a higher temperature than what your regular iron could give, so the color won’t come out as vibrant as you’d expect.

Since your iron can only cover a limited area at a time, pressing larger designs would be a struggle since you’d need to move your iron after several minutes. This could increase the possibility of blurring out your design or creating a white line when the heat overlaps.

The only exception you can use an iron for sublimation is when your design is small enough to fit the center part of your iron, so you won’t need to move it throughout the process.

Otherwise, it’s better to wait to get a heat press before you start thinking about adding sublimation printing to your services.

Final thoughts

When you’re having fun creating your own custom shirts, it’s only natural to start thinking about turning your hobby into a business where others can enjoy your work.

But since you’re still starting out, you don’t have the budget to get all the professional equipment you’ll need to run your business.

There’s no shame in using a clothes iron to print your shirts; you just need to be smart on what methods you can use to create successful prints.

Once your business starts picking up and more orders are coming in, a heat press would then help speed up your process without ruining their quality.

Leave a Reply